OrthoFlo

OrthoFlo is a CFD solver utilising the structured orthogonal meshing approach. Whilst this approach may introduce some limitations with respect to the complexity of the geometry that can be modelled, this approach can provide useful indicative results for some applications and may highlight whether a more comprehensive

analysis using a more advanced CFD code is necessary.

The first generation of the OrthoFlo code was written by Steve Howell of

Abercus, during his PhD studies at the University of Newcastle in 1998. Since

then, OrthoFlo has been developed through a second generation, captured in the

images below. Abercus is currently developing the third generation of the

OrthoFlo platform, which will benefit from the meshing capabilities more

recently developed as part of the OrthoMesh tool.

Second generation platform

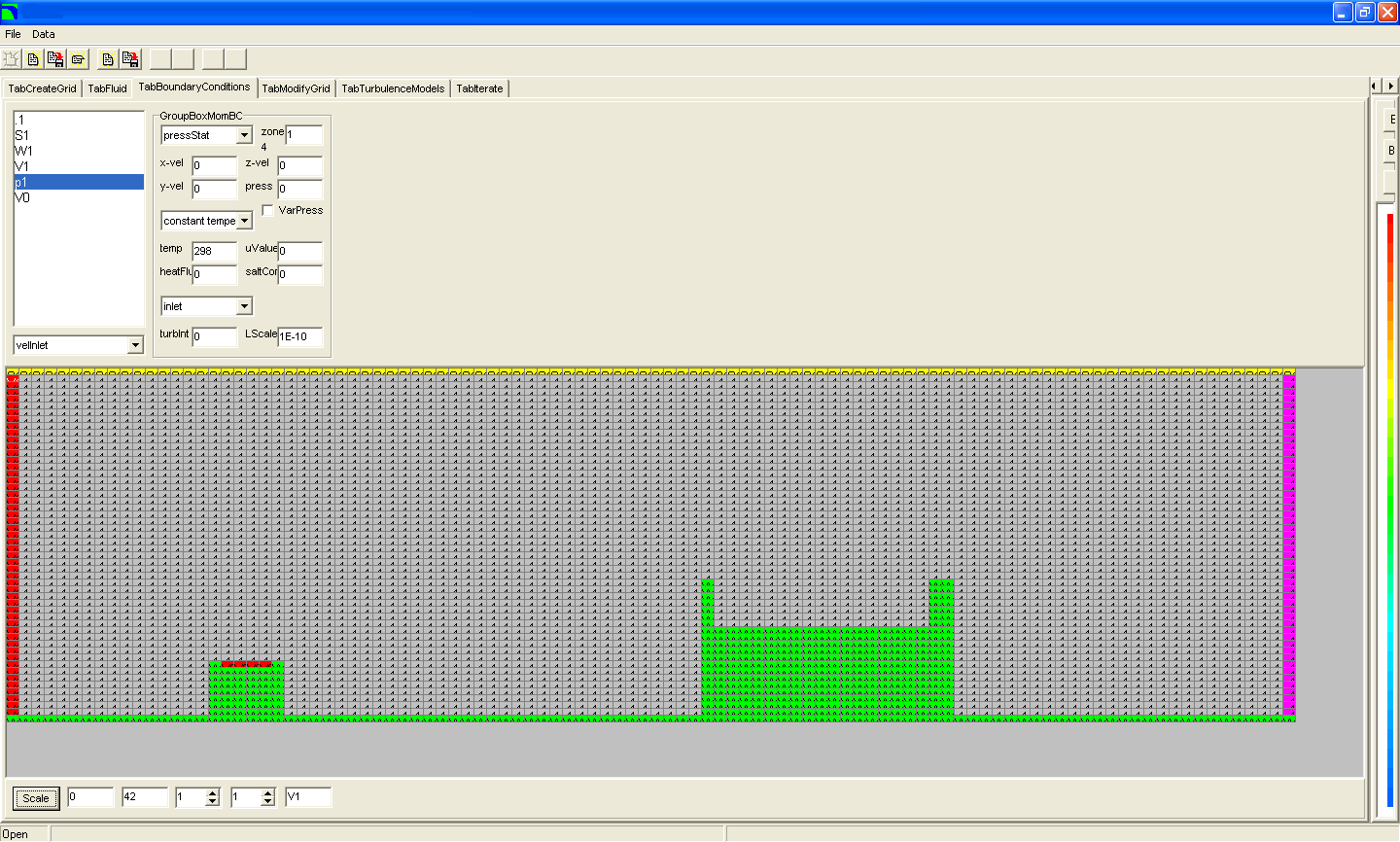

Mesh creation

Within the second generation platform, the computational mesh is manipulated by

selecting a boundary condition and then simply dragging over a rectangular array

of cells in the grid window, across which the boundary condition will be applied

- this interface was designed to mimic that of FLUENT 4, which was in widespread

use until the late nineties.

The image below shows the mesh for a two-dimensional atmospheric dispersion

example - whilst OrthoFlo is a three-dimensional CFD code, the two-dimensional

example shown is created by taking a 2D slice of the geometry and sandwiching it

between two symmetry planes.

The green cells are solid wall boundaries - the group of cells on the left represent

an exhaust stack and the group on the right represent some obstruction downstream,

whilst the lower edge represent the ground.

The red cells are velocity inlet boundaries - those on the left represent the incoming

wind flow, and those along the top of the exhaust stack represent the hot exhaust gas.

The yellow cells along the upper edge are symmetry cells, representing a slip condition for the sky.

The magenta cells along the right hand edge are static pressure cells, and allow the

flow to escape at the leeward extent of the model.

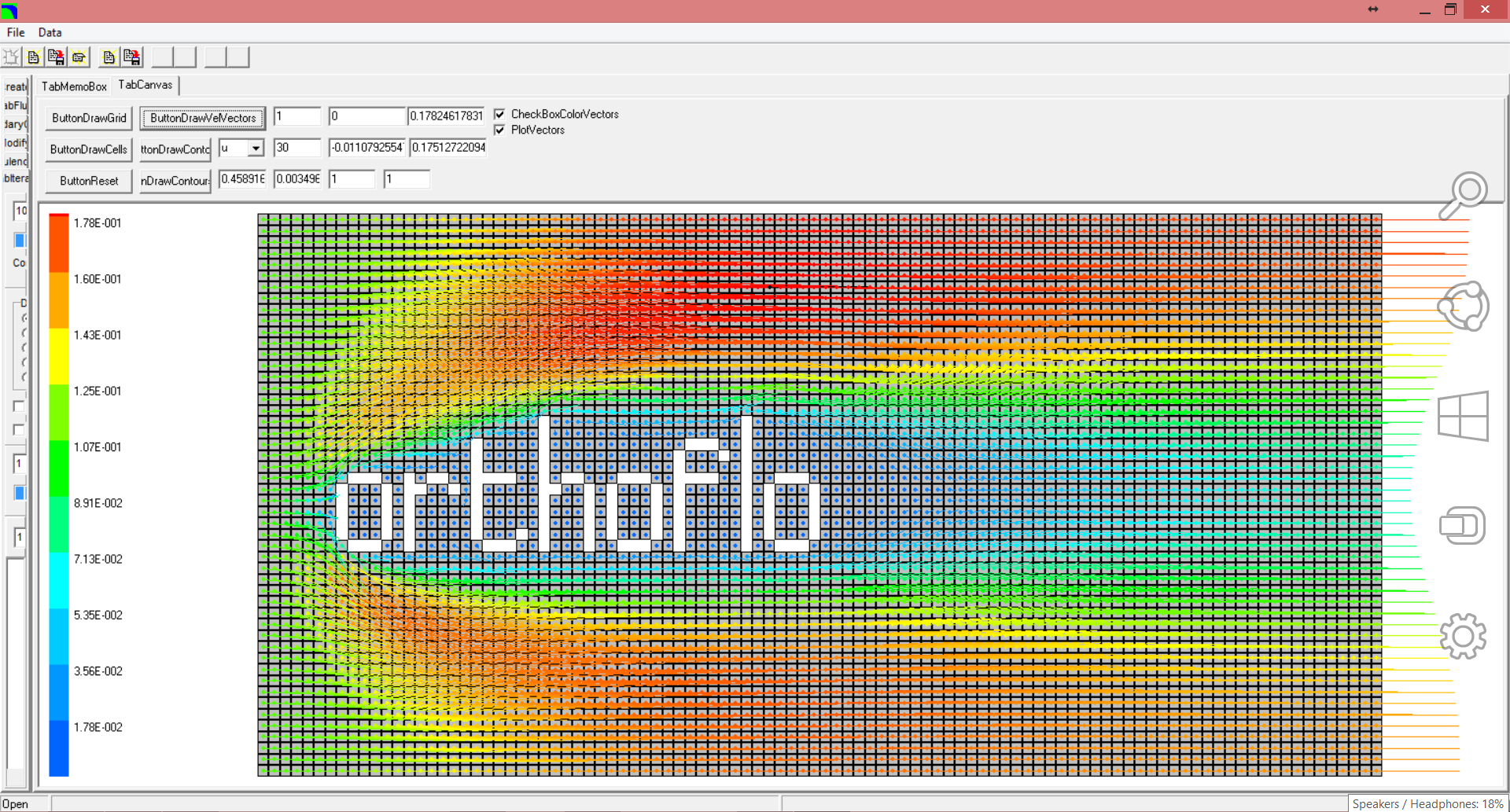

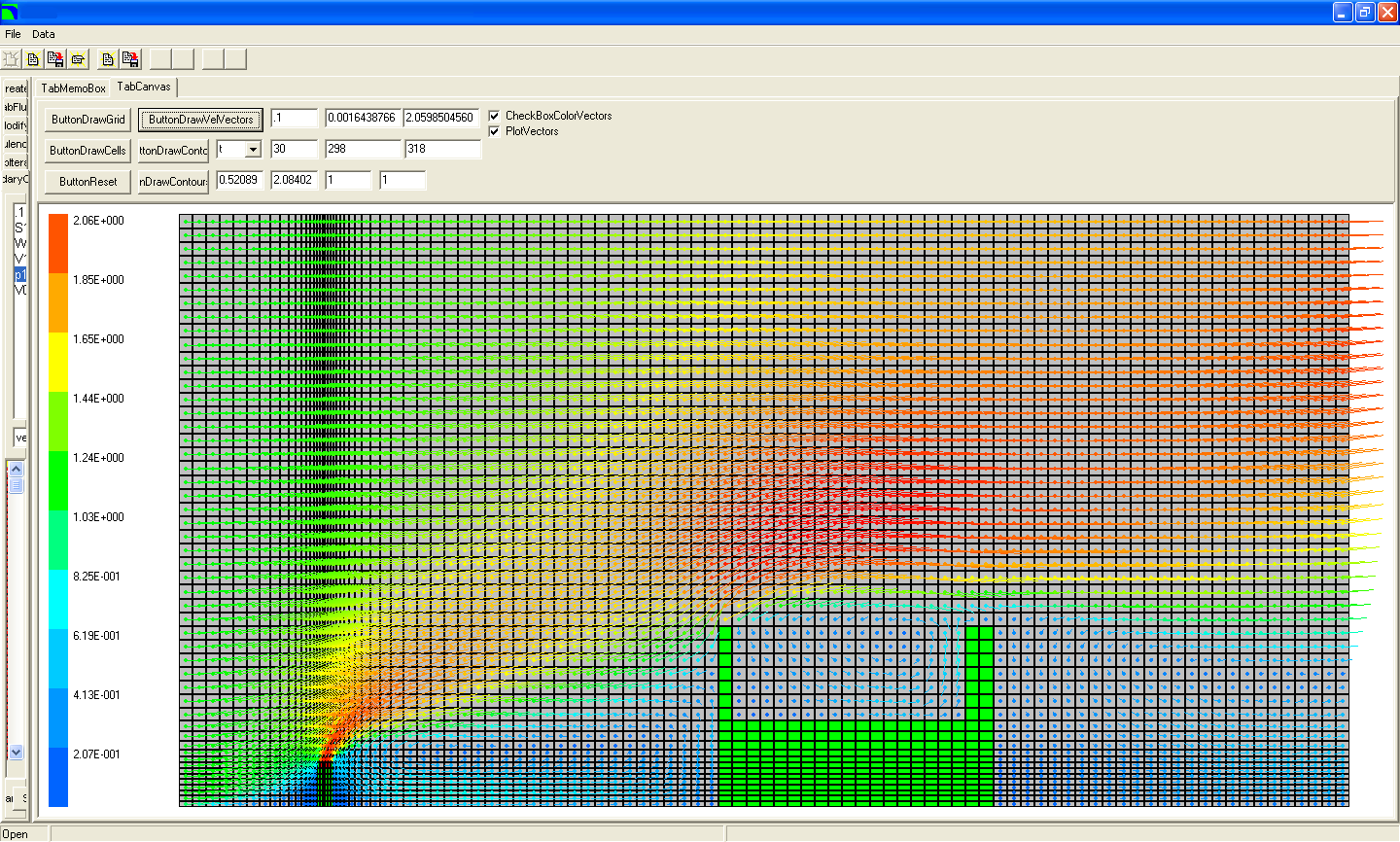

Vector plots

The velocity plot below shows the velocity vector predicted at each cell, coloured by local velocity magnitude.

The vector plot is superimposed over a plot of the geometrical grid. Notice that although mesh is necesarily

structured and orthogonal, it need not uniform - the image below shows the mesh refined in the regions of interest

around the exhaust stack.

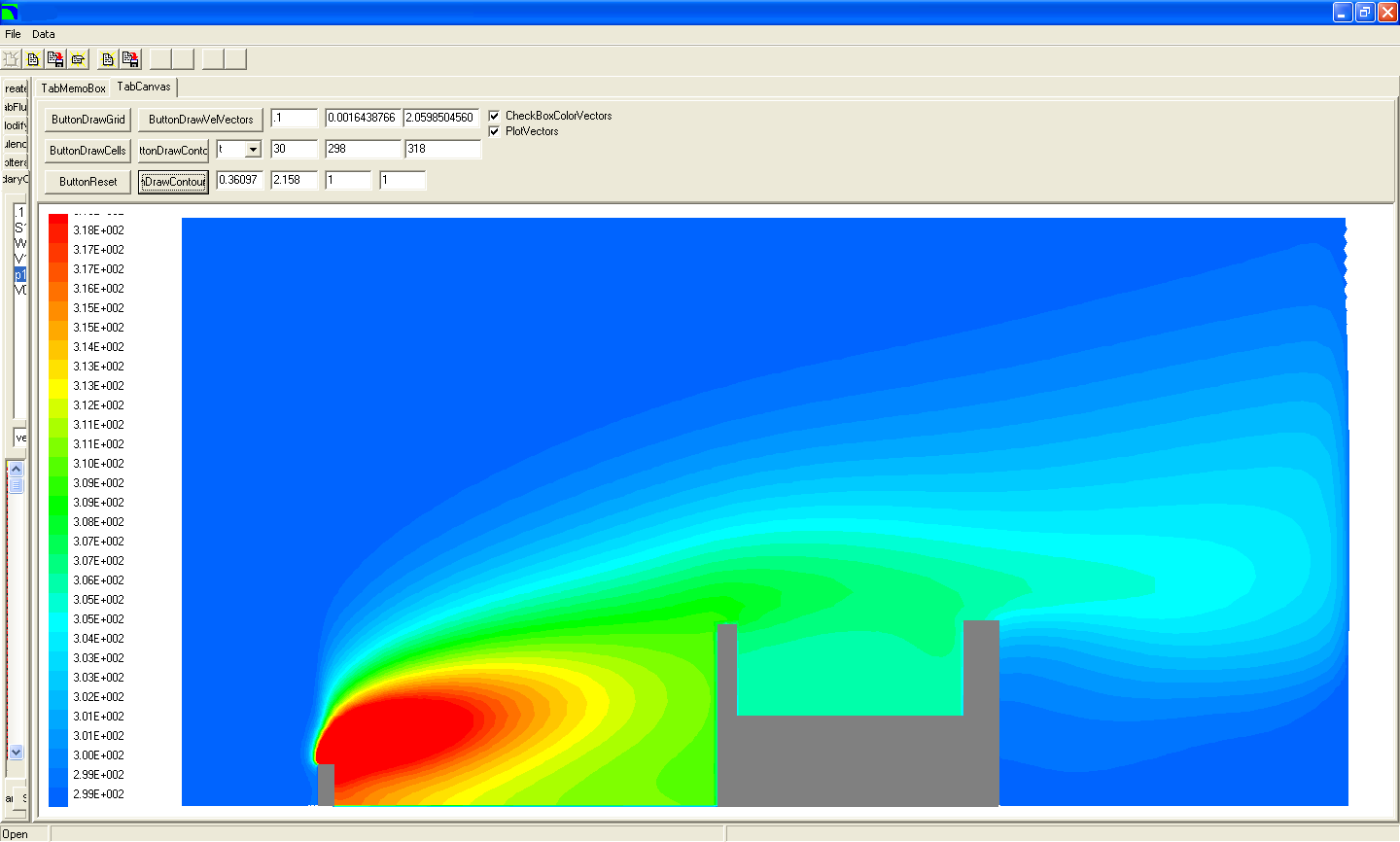

Contour plots

The contour plot below shows the dispersion pattern of the exhaust plume as it disperses over the obstruction further downstream.

The plot shows the plume to be drawn-down in the near wake of the exhaust stack

- this effect is particularly noticable for this two-dimensional example.